Metal Recycling

In addition to being the most recycled beverage package on the planet, beverage cans feature the most recycled content on average compared to other formats. Aluminum also offers the highest economic value among competing substrates. With these benefits, it is no wonder why 80% of all aluminum ever produced is still available for use today. A key differentiator with cans is that they are not only recyclable in theory, but they are actually recycled in practice. Consumers recycle aluminum cans at a rate of 69% on average, globally—more than double the rate that they recycle plastic bottles. In Europe, recycling rates exceed 76%, and in Brazil, numbers remain significantly higher than other substrates, at a near-100%. Yet, consumers can lack access to recycling infrastructure both publicly and privately and are often unaware of proper recycling measures or assume their recycled goods still end up in landfills. Therefore, many people do not recycle properly, keeping metal sustainability and other non plastic packaging solutions from reaching their full potential for recycling efficacy, particularly in the U.S.

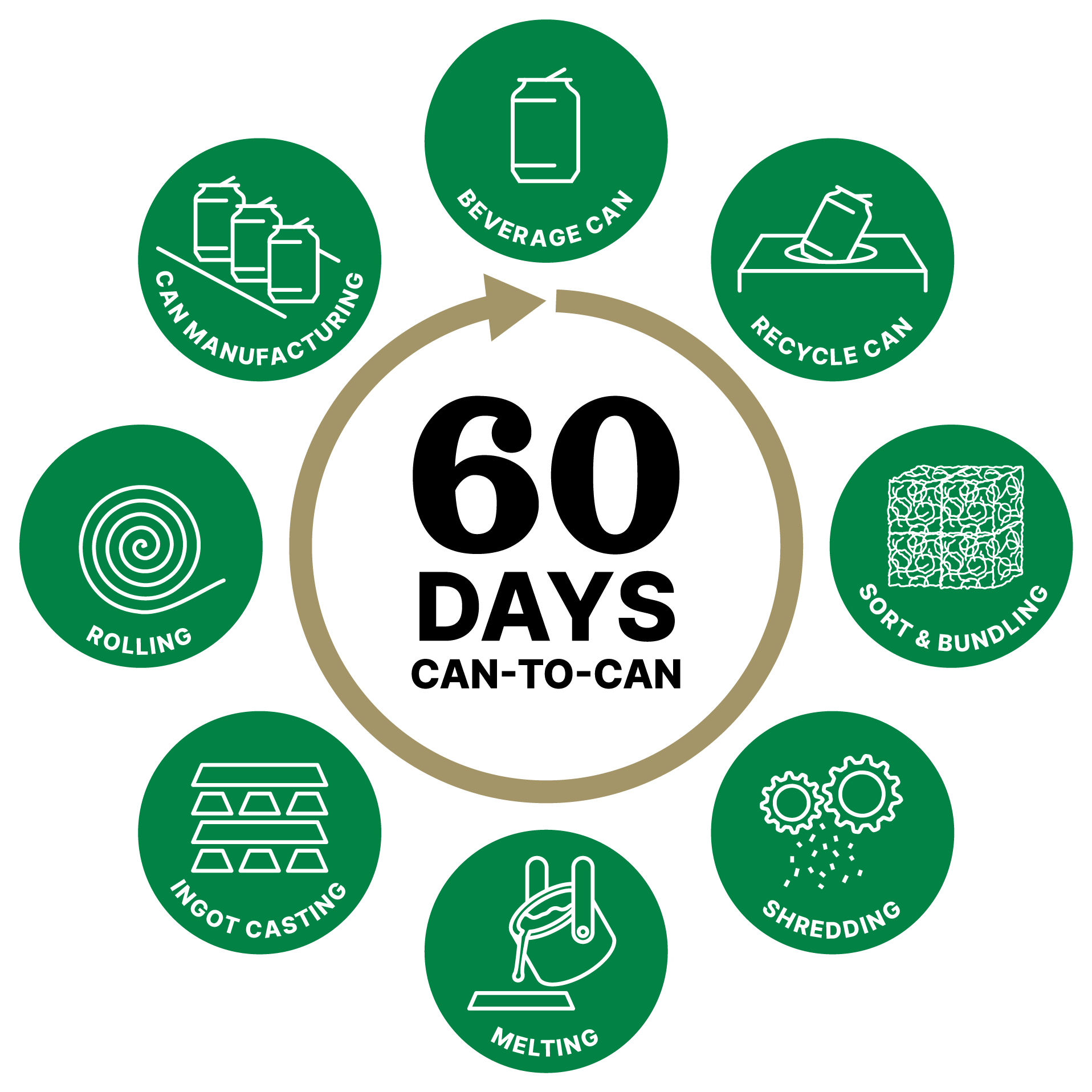

If you have ever wondered how the recycling process works, here is a brief overview:

- Cans are sorted and baled at a material recovery facility (MRF). MRFs are where all single stream recyclables are sorted. They are typically sorted out with the use of an eddy current and then baled for shipment to an aluminum recycler. Each baled cube of UBCs weighs about 2,200 pounds and contains about 65,000 cans.

- Bales of used beverage cans (UBC) arrive at an aluminum mill. There are several aluminum mills in the United States focused on melting UBCs to make can sheet for new cans with most of these mills in the Southeast United States.

- UBCs are prepared for melting. At the mill the cans are shredded into smaller pieces that allow for easier removal of the non-aluminum components. The shredded scrap goes through an optical sorter, which separates out the non-metal and blasts away plastic or glass with jets of air. It’s also put under a magnet that withdraws the steel. After these steps, the paint and lacquer are burned off, leaving only aluminum chips.

- Aluminum chips are melted and turned into can sheet. Furnaces at over 1200 degrees Fahrenheit melt the aluminum so it can flow into a mold and be cast into a towering block called an ingot. Each ingot weighs 27 tons and is made up of 1.5 million recycled cans. The ingots then go to a rolling mill where they are heated in another furnace to nearly 1000 degrees Fahrenheit. This relaxes the bonds so that as it is rolled back and forth, it thins out until can sheet is created that is about 33,000 feet long. The sheet is then rolled up and sent to a can manufacturer.

- The can manufacturer turns the aluminum can sheet into new cans. The can manufacturer unrolls the can sheet and feeds it into a cupping press, which cuts out shallow cups from the can sheet very rapidly. The left-over scrap after cutting out the cups goes back to the aluminum mill to be recycled. The shallow cups are rammed through a series of rings, each narrower than the last, creating the can’s iconic cylindrical can shape. The aluminum can is now ready for filling, enjoyment and then being recycled again.

Since metal is an infinite material that has no limitations for recycling and reproduction, its availability for future use is almost strictly dependent on how well it is captured and reused over time. That is why we are taking a more active role in guiding the material through its closed-loop system successfully—time and time again. For example, the Optimum Circularity pillar of our Twentyby30 sustainability program includes goals to increase the recycled content and recycling rate of our eco-friendly packaging products. We also recently set new global recycling targets to help propel the industry to the highest recycling rates possible.

Questions for Crown?