Can Manufacturers Institute Members Commit to Aluminum Beverage Can 70 Percent Recycling Rate by 2030

WASHINGTON, DC (November 10, 2021) – Can Manufacturers Institute (CMI) beverage can manufacturer and aluminum can sheet producer members are committing to achieving ambitious U.S. recycling rate targets including a 70 percent recycling rate by 2030. These new targets will improve the circularity of the aluminum beverage can while demonstrating to beverage companies and consumers the industry’s dedication to ensuring the aluminum beverage can remains the most sustainable package on the market.

The targets are being set through CMI, which represents U.S. metal can manufacturers and their suppliers. The aluminum beverage can recycling rate was 45 percent in 2020, and the industry aims to attain even higher recycling rates beyond 2030 with an 80 percent rate by 2040 and more than 90 percent by 2050.

CMI members are committed to more aluminum beverage cans completing the circular journey into new cans. There are nearly 90,000 aluminum beverage cans recycled every minute in the United States, with 93 percent going from the recycling bin back to store shelf as a new can in as little as 60 days. This high level of can-to-can recycling has resulted in the aluminum beverage can having an industry-leading average recycled content of 73 percent. Increasing the recycled content of the average can reduces its carbon footprint since making an aluminum beverage can from recycled material results in more than 90 percent less greenhouse gas emissions than making the container from primary material. Continued high demand for aluminum beverage cans necessitates the industry’s vision for increasing recycling of used beverage cans (UBC). Increased UBC recycling would enhance the resiliency of the domestic aluminum supply chain that is incorporated into new cans.

If the can industry’s new recycling rate targets are achieved, the U.S. recycling system also stands to gain since aluminum beverage cans are one of the most valuable commodities in the recycling stream. Aluminum beverage cans are only 3 percent by weight of all the recyclables at single-family U.S. homes, but they represent nearly half of the revenue of those recyclables. In fact, one recent study concluded that without the revenue from UBCs, most of the material recovery facilities that sort single stream recyclables wouldn’t be able to operate with their current business models. In short, collecting more cans means a financially strengthened U.S. recycling system.

The aluminum beverage can is starting from a position of strength. The aluminum beverage can was designed to be the premier package for recycling, and the can industry has invested billions of dollars so that cans are recycled in the United States at scale with existing infrastructure. The aluminum beverage can industry has been measuring its recycling rate for decades, and the last couple decades the rate has hovered around 50 percent.

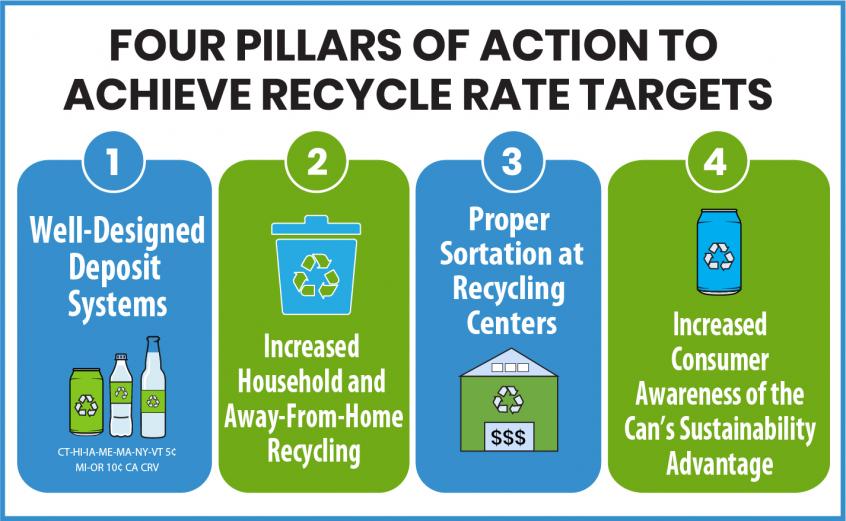

CMI’s approach to achieving its recycling rate goals will be to change consumer behavior through activities in four pillars of action:

- Catalyze the passage and implementation of well-designed deposit systems at the state and federal levels

- Increase and improve household and away-from-home recycling

- Ensure that more cans are properly sorted at recycling centers

- Increase consumer understanding on the importance of aluminum can recycling and the ability to collect and sell used beverage cans for cash

CMI members supporting the targets are aluminum beverage can manufacturers Ardagh Metal Packaging, Canpack, Crown Holdings and Envases; and aluminum can sheet suppliers Constellium, Kaiser Aluminum, Novelis and Tri-Arrows Aluminum.

“CMI’s aluminum beverage can recycling goals are inspired by our member’s commitment to sustainable and responsible world class, circular manufacturing processes,” said CMI President Robert Budway. “The industry is working collaboratively to increase recycling rates to benefit not only the industry’s growth, but also to strengthen the U.S. economy and play our part in planet stewardship.”

Using the first pillar of action as an example, the industry recently added to its thought leadership on the discussion around a well-designed deposit system. CMI published a joint statement in September 2021 with the PET plastic and glass bottle industries making clear that all three leading beverage container types support well-designed deposit systems. Further, CMI is advocating for a national deposit system in conversations with lawmakers.

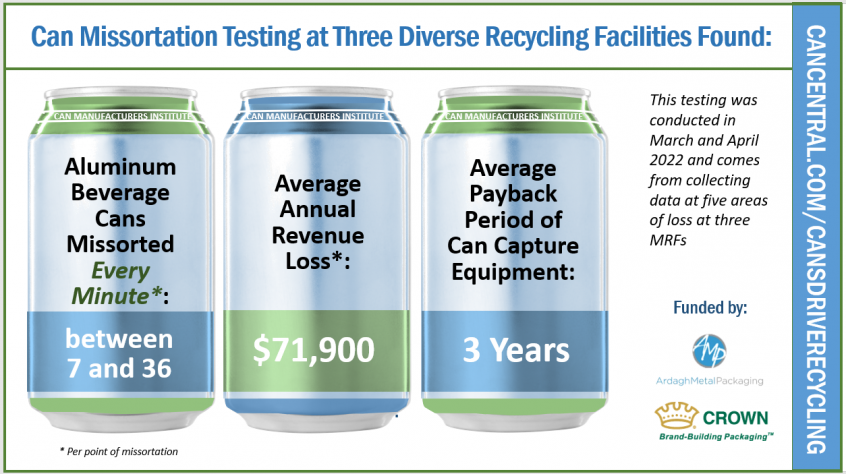

A strong example in the third pillar where the industry is already making strong strides is ensuring that more returned cans are properly sorted at recycling centers. Just two days ago, the fourth grant in a can capture program, funded by Ardagh and Crown in partnership with The Recycling Partnership, was announced for a Milwaukee area facility. Collectively, these four grants will lead to equipment installed that ensure the proper sortation and recycling of 67 million additional used beverage cans annually.

The environmental and economic benefits of greater aluminum beverage can recycling are astounding. If the aluminum beverage can recycling rate had been 70 percent in 2020, instead of 45 percent, there would have been around 25.6 billion more cans recycled, which would have generated more than $400 million in revenue for the U.S. recycling system and resulted in energy savings that could power more than 1 million U.S. homes for an entire year.

The industry will publish in early 2022 a roadmap with more details on how via these pillars the targets will be achieved.

Questions for Crown?